Components Manufacturing

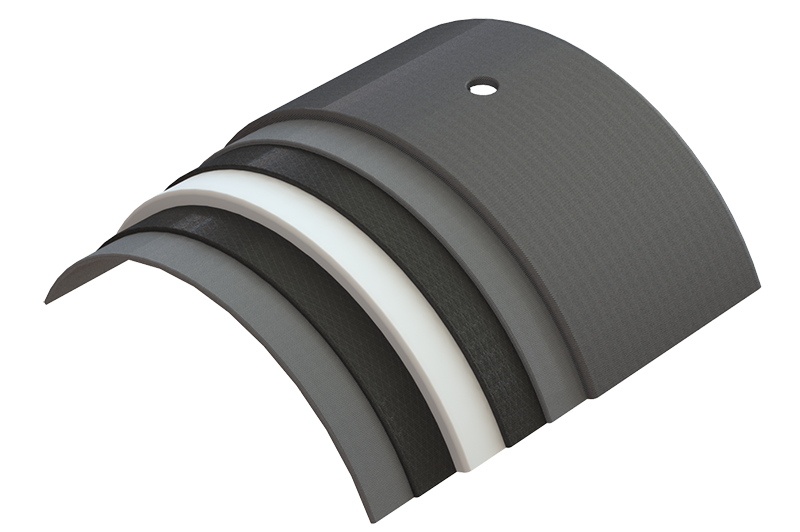

Multilayer composite components are manufactured utilizing a hot compression, molding method. These components are composed of a carbon and Kevlar® fiber-reinforced epoxy matrix with a proprietary high-wear resistance, low-friction outer layer. They are custom-designed to each client’s requirements.

Composite & Ceramic Centralizers

At Maxwell Oil Tools, from the beginning of every project, starting with the engineering, we want to make sure that each and every single product of our range of centralizers, drilling tools and special tools is built for purpose.

We have the solution to overcome our customer challenges.

Starting from the flexibility of design, which allows the optimal solution for each situation (ex. low impact geometry for restrictions / obstructions) to the final result where our composite and ceramic outside layer will provide a very low friction coefficient and high wear resistance but casing friendly product.

In addition to these features, our composite and ceramic centralizers as well as all our other drillpipe tools and special product line presents a very robust Construction with elevated mechanical properties.

Our products are also non-metallic and inert, they are millable and drillable and there is no need for stop collars or set screws.