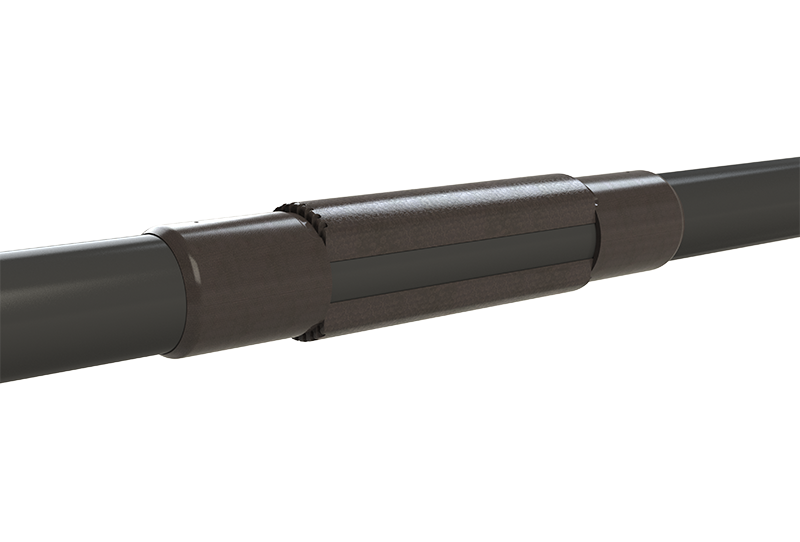

CLIMAX – Annular Relief Pressure System

Pressure relief pistons are embedded in the central MCC shell which is held in place with bonded end rings using the MCC Installation process. The low-friction shell provides wear resistance and protection to pistons. As annular pressure increases, the pistons depress into the chamber creating more volume and stabilizing pressure.

Advantages

- Can be installed onto the tubular in any configuration

- Gas-filled chamber pressure rating can be customized according to requirement

- Number of units can vary according to volume requirement

- Units can be staggered to allow for maximum fluid bypass

- Unlimited number of cycles to compensate pressure build-up during the entire life of the well

CLIMAX – Bonded to Tubular – Transversal View