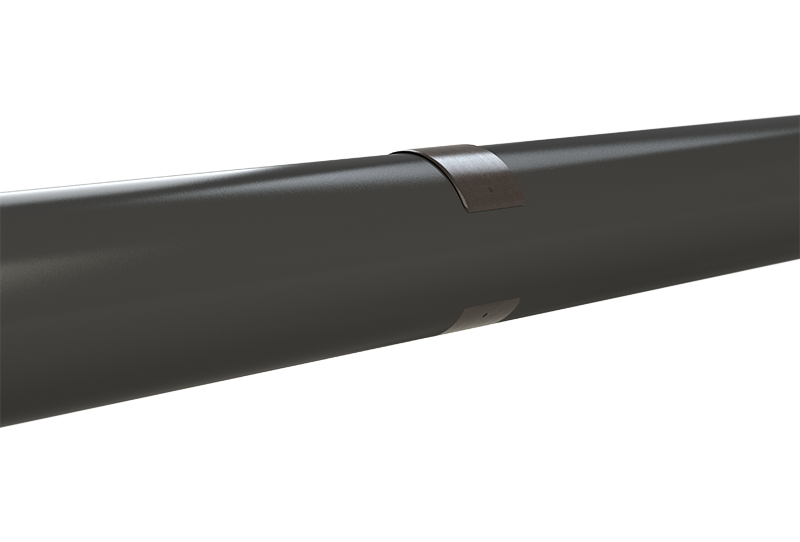

MAXSTOP Tight Tolerance

MAXSTOP Tight Tolerance is a low friction, highly abrasion resistant, all composite bonded Stop Collar purposely conceived for tight tolerance application.

MAXSTOP Tight Tolerance has a maximum height of 0,2”.

The parts are bonded in place, axially and radially, by vacuum injecting a modified structural epoxy system into a profiled cavity between part and tubular body, thereby eliminating the need for collars or screw mechanisms.

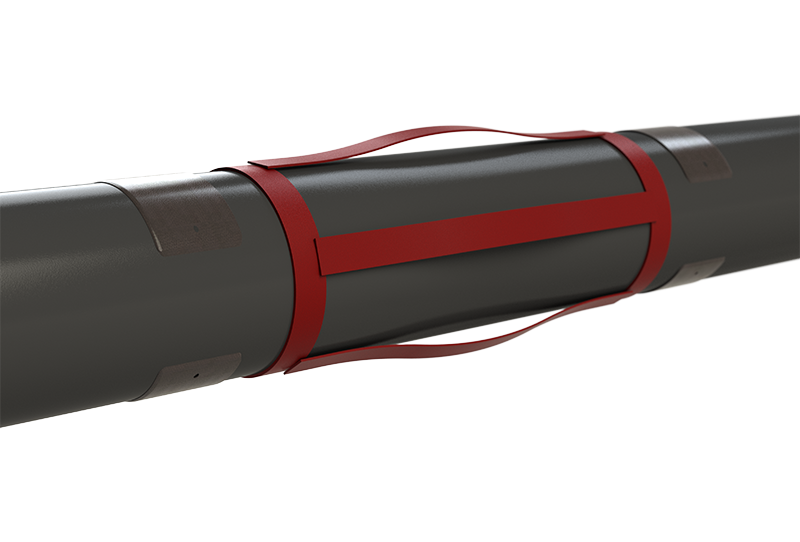

MAXSTOP Tight Tolerance can be used with any 3rd party centralizer or casing accessory.

MAXSTOP Tight Tolerance rotates with the pipe once installed.

MAXSTOP Tight Tolerance is non-corrosive, non-invasive, has extremely high holding forces.

MAXSTOP Tight Tolerance isn’t impacted by non-ovality or pipe API tolerances.

The system is field proven and shows excellent results.

MAXSTOP Tight Tolerance – Bonded to Tubular with Bow