SCREENSAVER™

Protects and delivers your Screens to TD.

The SCREENSAVER™ is a low friction, highly abrasion resistant, all composite screen protector. The two parts are bonded in place, axially and radially, by injecting a modified structural epoxy system into a profiled cavity between part and tubular body, thereby eliminating the need for collars or screw mechanisms.

Once installed, the tools provide screen protection together with a low friction outer surface, making the tool a beneficial asset for ERD and horizontal completion. The pad surface area is engineered to optimize weight distribution, SCRENSAVER™ will not dig into formation / cuttings bed. The staggered pads minimize any restriction to annular flow and avoid build up of debris while running in horizontal sections.

The system is field proven and shows excellent results even under very aggressive drilling conditions.

Advantages are:

- Friction reduction

- Minimizes differential sticking

- Bonded to base pipe – no collars or grub screws

- All composite – No galvanic corrosion

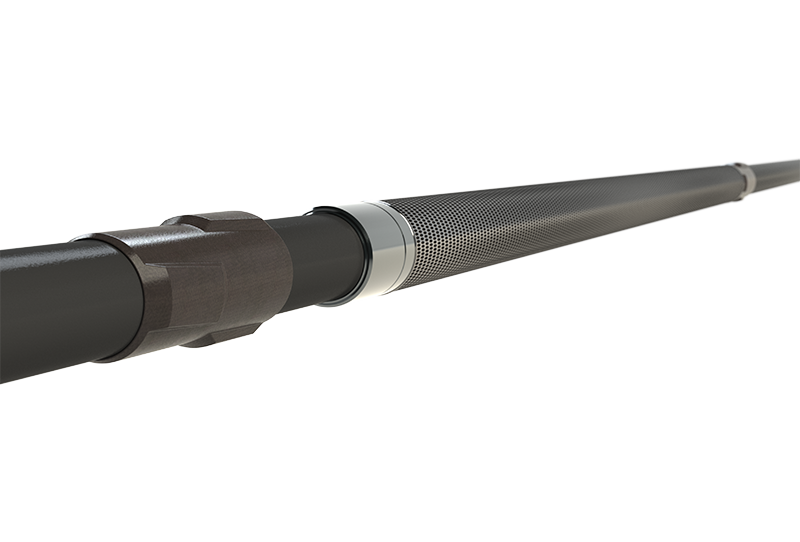

SCREENSAVER – SP Bonded to Tubular – Detail

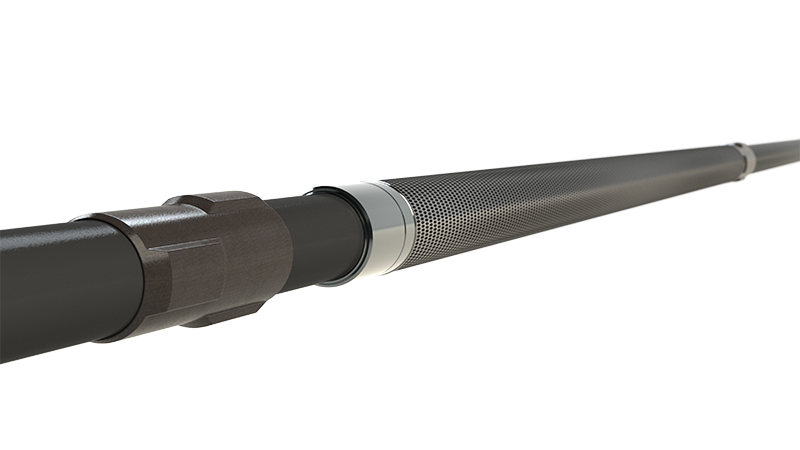

SCREENSAVER – ST Bonded to Tubular

SCREENSAVER – ST Bonded to Tubular – Detail